In the world of electronics, managing heat is crucial for ensuring optimal performance and longevity. Overheating can degrade components, reduce efficiency, and even cause complete system failures. To combat this issue, thermal management solutions like thermal pads have become essential. Thermal pads are soft, compressible materials designed to fill air gaps between heat-generating components and heat sinks, allowing for efficient heat transfer.

Millennium Semiconductors, as a distributor for leading suppliers, provides high-performance thermal pads for a wide range of electronic applications. Understanding their function and benefits is key to improving device reliability and efficiency.

Where Are Thermal Pads Mostly Used?

Thermal pads are widely used across various industries and applications where efficient heat dissipation is critical. Some common areas where they are applied include:

- Computers & Laptops – Used in CPUs, GPUs, and power regulators to prevent overheating.

- Automotive Electronics – Essential for in-vehicle electronic control units (ECUs), battery management systems (BMS), and LED lighting.

- Power Electronics – Applied in power transistors, inverters, and converters to maintain optimal performance.

- LED Lighting – Helps in dissipating heat generated by high-powered LEDs, ensuring longer lifespan.

- Telecommunication Equipment – Used in networking devices, routers, and base stations.

- Consumer Electronics – Found in gaming consoles, smartphones, and home appliances.

How Are Thermal Pads Helpful in the Electronics and Semiconductor Industry?

With the continuous miniaturization of electronic components, managing heat efficiently has become a significant challenge. Thermal pads offer a practical solution by:

- Improving Device Lifespan – By reducing excessive heat, thermal pads prevent damage to sensitive semiconductor components.

- Enhancing Performance – Devices operate at peak efficiency with controlled temperatures.

- Providing Electrical Insulation – Many thermal pads offer insulating properties, reducing the risk of short circuits.

- Ease of Application – Unlike thermal grease, thermal pads are easy to apply and do not require curing or reapplication.

How Do Thermal Pads Improve Heat Dissipation?

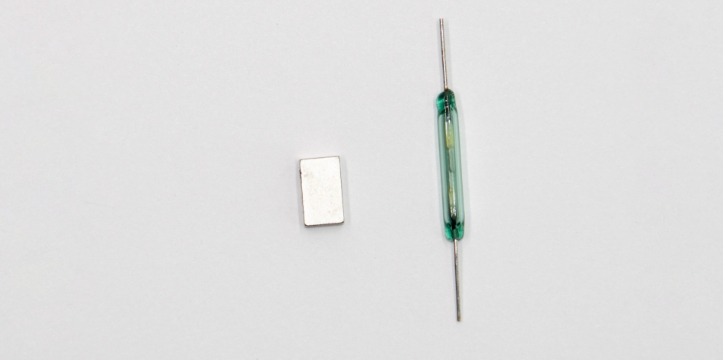

Thermal pads play a critical role in heat dissipation by filling microscopic air gaps. It will naturally exist between heat sources (such as processors, transistors, or power modules) and heat sinks or cooling solutions. Air is a poor thermal conductor, so these gaps can cause inefficient heat transfer, leading to overheating.

A thermal pad improves this process by:

- Ensuring Full Contact – The pad conforms to the irregular surfaces of electronic components, maximizing heat transfer.

- Increasing Thermal Conductivity – Made from thermally conductive materials like silicone, graphite, or ceramic-filled polymers, thermal pads facilitate efficient heat movement.

- Providing Even Heat Distribution – They prevent localized overheating by spreading heat evenly across the heat sink.

How to Apply a Thermal Pad?

Applying a thermal pad correctly is crucial for optimal performance. Here’s a step-by-step guide:

- Clean the Surface – Remove any dust, old thermal material, or debris from the contact surfaces using isopropyl alcohol and a lint-free cloth.

- Measure & Cut (If Required) – Many thermal pads come in standard sizes, but some may need to be trimmed to fit precisely.

- Peel Off Protective Layers – Most thermal pads have a protective film on both sides that should be removed before application.

- Place the Thermal Pad – Position it evenly on the heat-generating component.

- Apply Gentle Pressure – Press down lightly to ensure full contact with the surface.

- Assemble the Heat Sink – Secure the heat sink in place to complete the thermal management setup.

Are Thermal Pads Necessary?

Yes, thermal pads are essential in many electronic and semiconductor applications due to their ability to efficiently transfer heat. Without proper thermal management, electronic devices can overheat, leading to performance degradation, reduced lifespan, and potential safety hazards.

While some applications may use alternatives like thermal grease, thermal pads offer a cleaner and more durable solution, particularly in scenarios where reapplication is not practical.

What is the Difference Between Thermal Pads and Thermal Grese

| Feature | Thermal Pads | Thermal Grease |

| Ease of Application | Simple peel-and-stick application | Requires careful spreading |

| Reusability | Can be reused if undamaged | Needs reapplication over time |

| Messiness | Clean and straightforward | Can be messy and difficult to clean |

| Performance | Slightly lower but sufficient for most applications | Higher thermal conductivity |

| Electrical Insulation | Offers insulation in many cases | Usually non-insulating |

Thermal pads are a vital component in thermal management for various electronic and semiconductor applications. Therefor, their ability to fill air gaps, improve heat transfer, and provide insulation makes them an excellent choice for engineers and manufacturers seeking reliable cooling solutions.

As a leading distributor of thermal management solutions, Millennium Semiconductors offers high-quality thermal pads from leading manufacturers to ensure efficient heat dissipation across industries. Whether you are working with power electronics, automotive systems, or consumer devices, choosing the right thermal pad can significantly enhance your product’s performance and longevity.

For expert guidance and high-quality thermal solutions, connect with Millennium Semiconductors today!

info@millenniumsemi.com

info@millenniumsemi.com Sales: 8411005848 | HR: 02027484800

Sales: 8411005848 | HR: 02027484800